Curd Draining

Provolone draining and ripening systems

Design, manufacturing and installation of curd draining and ripening machineries for the production of provolone.

The curd is conveyed to the draining expansion chamber. The draining strainer separates the curd’s grains from whey. Afterwards, the curd’s grains are directly conveyed to the first curd’s ripening, cutting and overturning vat. In the secondo ripening, cutting and overturning vat we have the possibility to let the cheese ripen for the desired period of time. Furthermore, it is possible to execute one or more pasta accumulation in order to guarantee the best whey discharge possible. In the final part of the machinery, the pasta gets divided into blocks ( the size of the blocks can be customized ) and it is made available to the stretcher. The curd draining and ripening lines are already prepared for the C.I.P.

It is possible to record all the relevant data ( curd temperature, temperature of the hardening environment, amount of drained product, time of discharge, hardening duration, number of curd accumulations, etc… ) and to transfer them to the company computers to allow the traceability of the production batch.

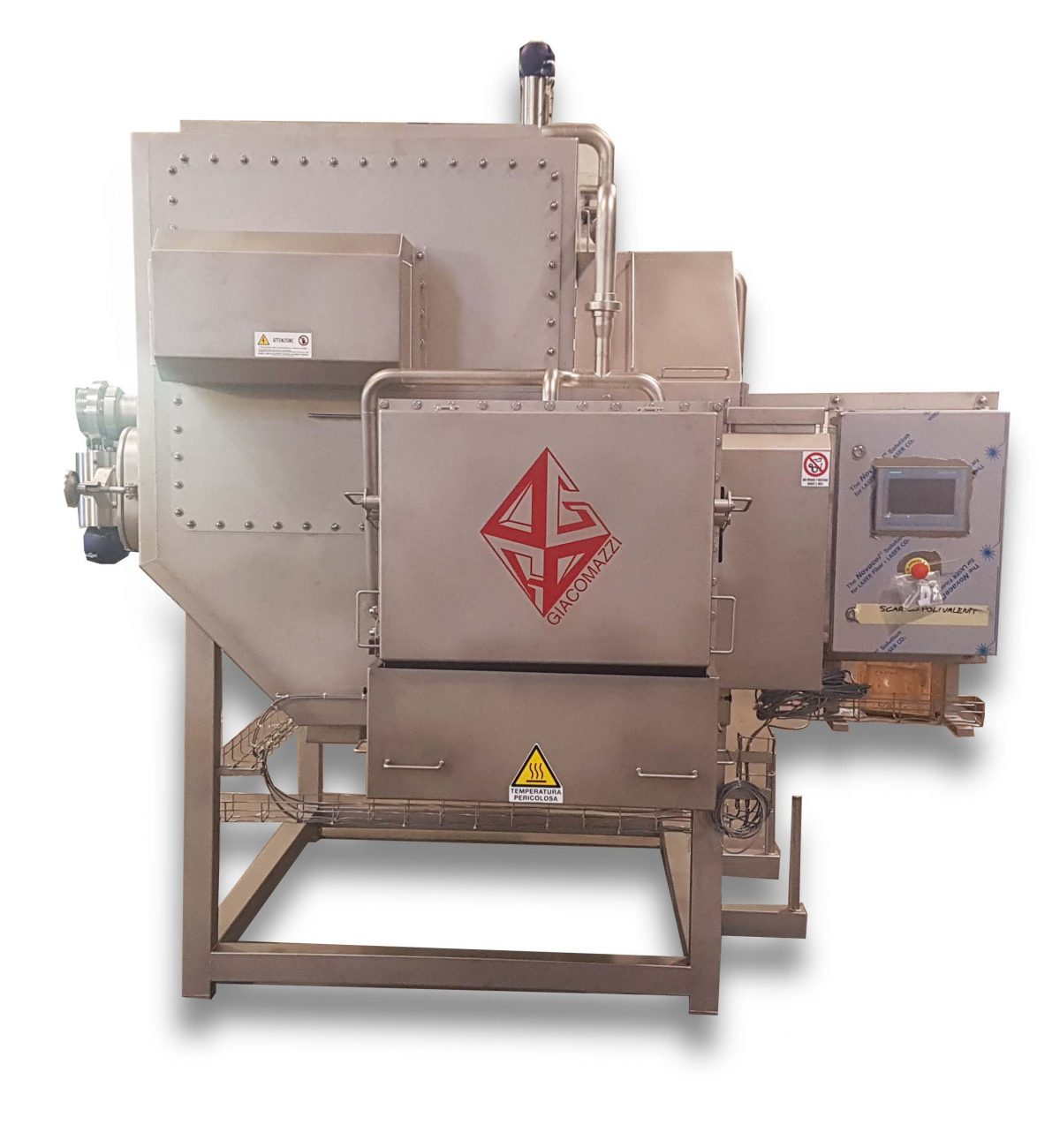

Draining and maturation of curd with three cuts and tilting. Production of seasoned provolone, coagulation with polyvalent from 10000 liters.

Curd drainage and maturation plant for sweet provolone.

Curd during ripening.

Draining and curd maturation with 4 cuts and toppings, production of seasoned provolone, coagulation with 13,000 liters polyvalent.

Drainage tank and transfer to curd maturation. Capacity: 2 multiples of 13,000 liters.

Mozzarella draining and ripening systems

Design, manufacturing and installation of mozzarella draining and ripening systems.

The product is composed of curd and whey and it is unloaded on the conveyor belt thanks to two self-levelling unloading pipes that allow the product’s constant descent and prevent the curd grain beak-up and the following yield loss. The quantity of pre-drained product accumulates on one belt, which is supplied with a gear motor. In this way, it is possible to obtain on homogenized curd layer on the entire surface of the draining belt. During the ripening time, the draining of curd continues from the containment sides, which are made with filtering material sheet in their upper part.

The last draining takes place during the cutting step, before the product’s unloading when it is ready for the stretching ( filatura ). The mozzarella draining and ripening system is already prepared for the C.I.P.

It is possible to record all the relevant data ( curd temperature, temperature of the hardening environment, amount of drained product, time of discharge, hardening duration, number of curd accumulations, etc… ) and to transfer them to the company computers to allow the traceability of the production batch.

Drainage and maturation system of the curd for mozzarella with automatic service to the machines.

Draining and maturation of the curd for mozzarella.

Drainage and maturation system of the curd for mozzarella with automatic service to the machines.

Drainage and maturation system of the curd for mozzarella with automatic service to the machines.

Draining and maturation of the curd for mozzarella.

Curd draining roller

Curd draining roller

Curd draining roller