Special Lines

Caciotta cheese

Automatic and semi-automatic machineries that allow the production of hard and semi-hard cheese, are planned and realised according to the client’s production needs ( namely in terms of size, weight, potential flavourings, olives, nuts, etc. ). We can build automatic machineries complete with C.I.P. cleaning system, where the operator is only a supervisor.

Caciotta cheese semi-automatic line

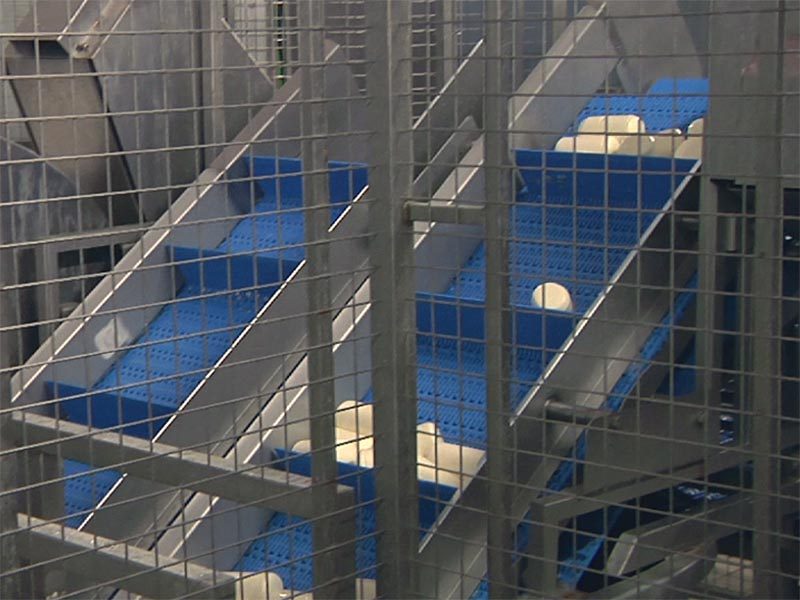

Moulds tilter

Operating moulds tilter.

Manual distribution for caciotte.

Conveyor belt for caciotte.

Automatic press for caciotte.

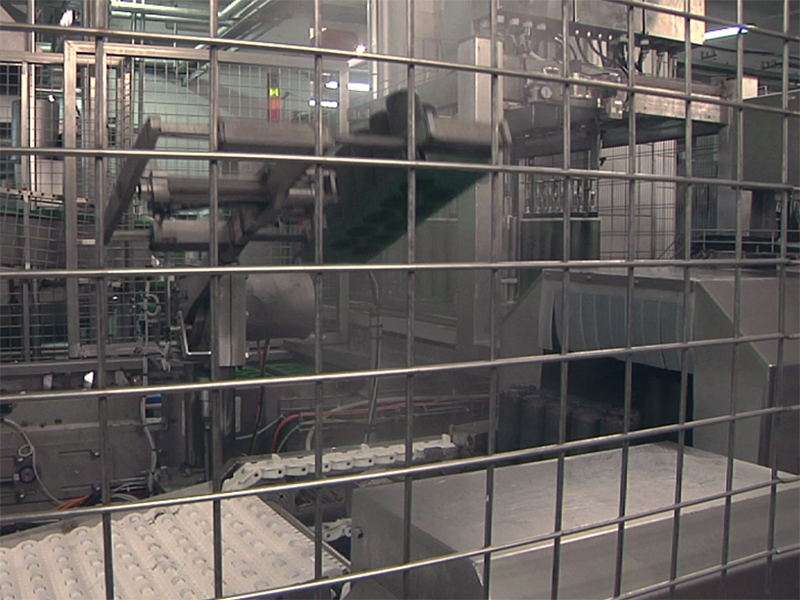

Automatic feeding line for caciotte.

Automatic lines

Our “special” plants are completely made of stainless steel AISI 304 / AISI 316, sheet metal, sections and food-safe plastic materials. The sanitary type construction allows an optimum and easy cleaning. In the inner parts there are no sharp edges but only suitably connected angles with wide radii of curvature to avoid stagnation areas. Internally and externally polished pipes complete with valves in stainless steel AISI 304 / AISI 316.Main characteristics:

• Customized design of the line / plant based on the hourly capacity, type of product and section layout.

• Metalwork in Stainless Steel AISI 304/316.

• Plastic materials with food-safe certifications.

• Construction and assembly of the sanitary type.

• Electrical panel in Stainless Steel IP65.

• Software management with implementation of the working batches.

• Pre-arranged for the C.I.P. cleaning.