Products

heat treatment of milk

We all know how important it is to properly preserve a raw material as precious as your milk. For this reason we make different sizes of stainless steel tanks AISI 304/AISI 316, with the possibility to record the relevant data ( temperature, quantity, uploading and unloading time, etc.. ).

Our company designs, builds and installs:

Plate heat exchangers for the treatment of milk upon receipt

Milk pre-heating plants for the subsequent processing and cheese-making phase.

Milk pasteurization plants

Pasteurization plants and milk degassers

The data can be transferred to the company computers in order to allow the traceability of the production batch.

Heat treatment of raw milk with fat titration

Heat treatment of raw milk with fat titration

Pasteurizer with 20 second tubolar exchanger

4-line degasser

Pasteurizer with 20 second tubolar exchanger

Coagulation

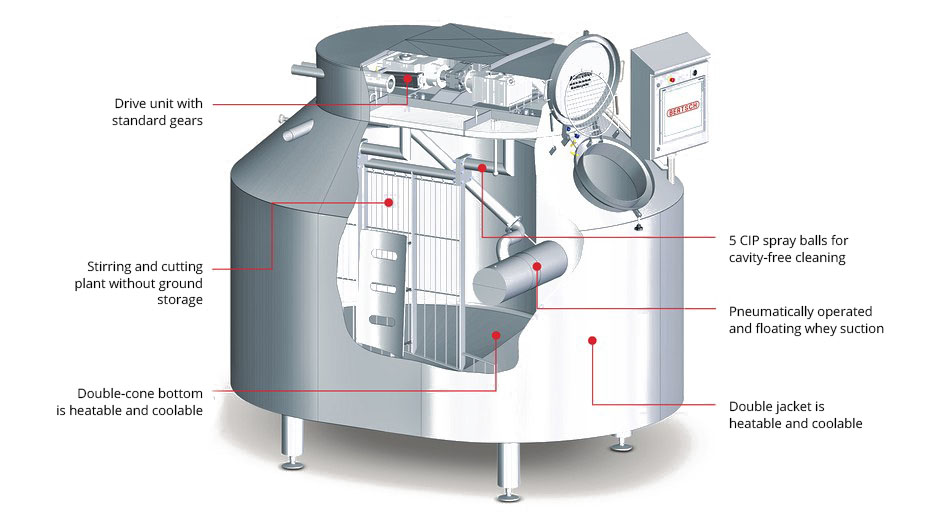

Bertsch Universal cheese vats mod. DK – Double-O- cheese vat design, double-cone shaped product compartment for fixed horizontal installation; it is intended for the production of semi-hard cheese, pasta filata and kasar. Steam-heated walls and bottom. External jacket with air isolated gap.

Content ( lt ): 500 – 1.000 – 4.000 – 6.000 – 8.000 – 10.000 – 12.000 – 15.000 – 20.000 – 25.000 – 28.000.

Entire cheese vat made of cold-rolled stainless steel (except gear system).

Equipment:

Built-in suction basket. Whey suction takes place via a floating pneumatically-operated suction basket that, thanks to the floatation on the surface of the content, allows a fast suction of the whey without sucking in air.

Electrically wiring and control system for cheese vats:

Manual

Semi-automatic

Automatic

Coagulation stop

Cheese vat first cut

Two 10.000 lt cheese vats with copper inner jacket ready to be delivered

15.000 lt cheese vat for mozzarella

10.000 lt cheese vat for mozzarella

8.000 lt cheese vat for mozzarella

8.000 lt cheese vat for sheep’s milk

Drainage and Maturation

Provolone drainage and maturation system

Design, construction and installation of curd drainage and curing lines for provolone / pizza cheese / scamorza …

The curd is conveyed into the drainage expansion chamber. The draining filter separates the curd granules from the whey and transfers them directly to the first tank of maturation, cutting and overturning of the curd. In the second tank of maturation, cutting and overturning we have the possibility to mature the curd for the desired time and to perform one or more piles of the curd to ensure an optimal purging of the whey. At the end of the line, the curd is cut into blocks and made available for the spinning line.

Mozzarella drainage and maturation system

Design, construction and installation of curd drainage and curd lines for mozzarella. The product consisting of curd and whey is discharged onto the conveyor belt thanks to two self leveling exhaust pipes, which maintain a constant product drop height. The mass of pre-drained product accumulates on a belt which, moved by a geared motor, allows a homogeneous and uniform layer of the curd on the entire surface of the drainage belt. During the maturation time, the curd continues its drainage from the containment sides that in the upper part are made with the filtering plate. The last drainage takes place during the cutting phase, before the discharge to the product ready for spinning.

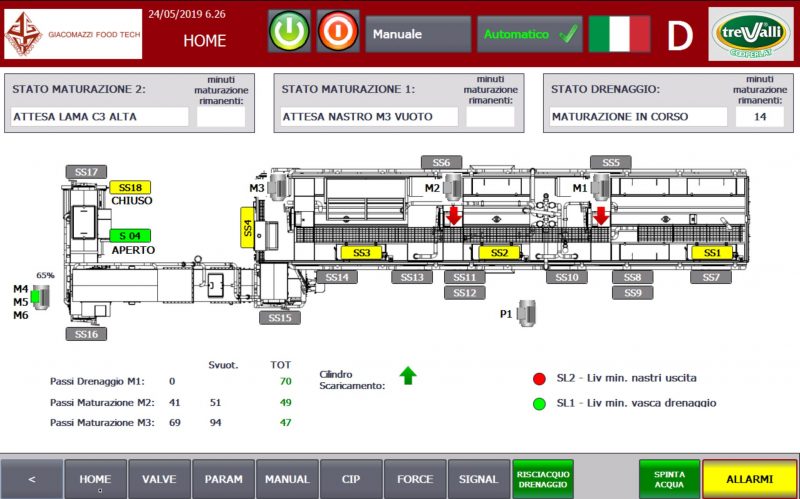

Display of the drainage system operator’s panel

Provolone drainage and maturation system

Mozzarella drainage and maturation system

Automatic curd drainage system Adjustment of the desired curd thickness | Automatic system for cutting and overturning the curd slices

Curd self-leveling system | Adjustment of the desired curd thickness | Automatic system for cutting and overturning the curd slices

Curd during ripening

CIP washing circuit | software system for automatic management of the plant Supervision system for the collection of production data

CIP washing circuit | software system for automatic management of the plant Supervision system for the collection of production data

Drainage system with stretcher feeding line

Drainage system with stretcher feeding line

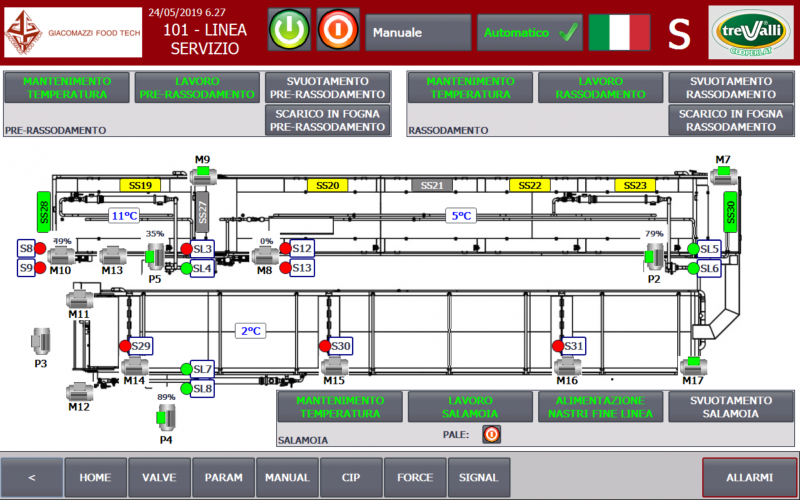

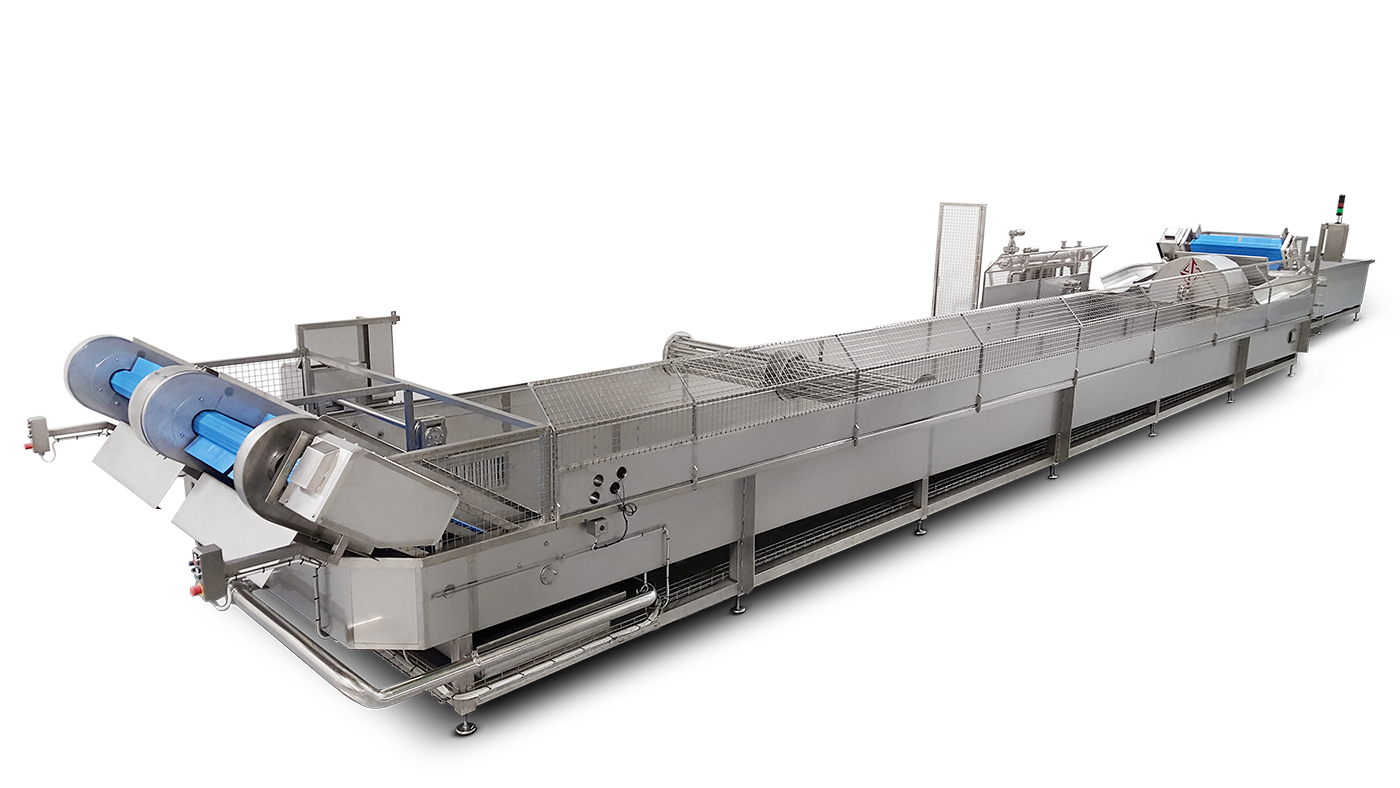

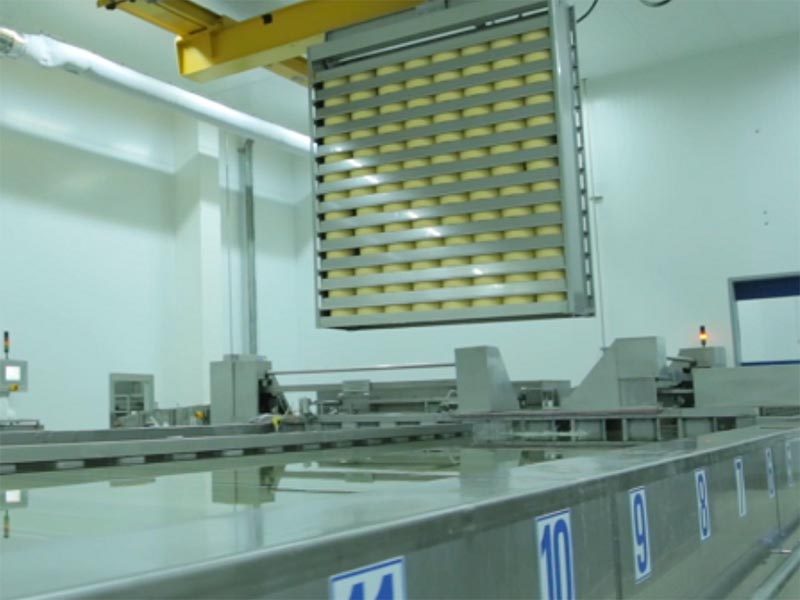

Hardening lines

The pre-hardening and hardening lines are totally built in Stainless Steel AISI 304 / AISI 316, sheet metal, sections and food-safe plastic materials. The sanitary type construction allows an optimum and easy cleaning. In the inner parts of the vat there are no sharp edges but only suitably connected angles with wide radii of curvature to avoid stagnation areas. The product is carried through a mobile panel that pushes forward the product at each step. The extraction conveyor is food-safe certified. Internally and externally polished pipes complete with valves in stainless steel AISI 304 / AISI 316. The line is provided with water treatment and cooling units.

• Customized design of the hardening line based on the hourly capacity, type of product and section layout.

• Metalwork in Stainless Steel AISI 304/316.

• Plastic materials with food-safe certifications.

• Construction and assembly of the sanitary type.

• The product-forward system can be set through the operator’s panel.

• Automatic system for the product extraction.

• Water filtration and fat collection system.

• Automatic control of the temperatures.

• Control and automatic management of the residence time and cooling of the product.

• Electrical panel in Stainless Steel IP65.

• Software management with implementation of the working batches.

• Pre-arranged for the C.I.P. cleaning.

Hardening tunnel for small size mozzarella

Display of the hardening and brining system operator’s panel

Working pre-hardening and hardening line

Pre-hardening and hardening line

Working hardening line

Working hardening line

Unloading hardening line

Brining lines

Brine’s automatic system is entirely built in stainless steel AISI 316 metal sheet. Section bars and plastic materials intended to come into contact with food. Its sanitary construction allows an easy cleaning. The internal part of the vat is realised in such a way that there are no sharp edges, but curved edges in order to avoid stagnation. The product’s convey takes place due to power produced by a rotor. The hinged extraction belt is certified and intended to come into contact with food. All pipes are internally and externally polished and they are complete with valves realised in stainless steel AISI 316.

Main characteristics:

Brine dynamic system

Brine dynamic system

Operating brine dynamic system

In-ground brining system

System for the extraction of the brining product

Handling of the product coming out of the brining

Brining line loading – unloading

Brining line automatic loading

Brining line loading

Working brining line

Brining line

Brining system movement

Ricotta cheese

Design and production machineries composed of:

5.000 lt flocculators

5.000 lt flocculator

Ricotta cheese draining system

Curds accumulating vats

In the construction of this type of machinery we consider the specific food processing in which the equipment is going to be employed. Once the curd accumulating vat is loaded, either manually or automatically, it allows the constant and autonomous supply to the stretcher for approximately 20 / 25 minutes and, after that, it is ready for a new load.

Polmone di accumulo cagliata

Operating curd accumulating vat

Curd accumulating vat on automatic line

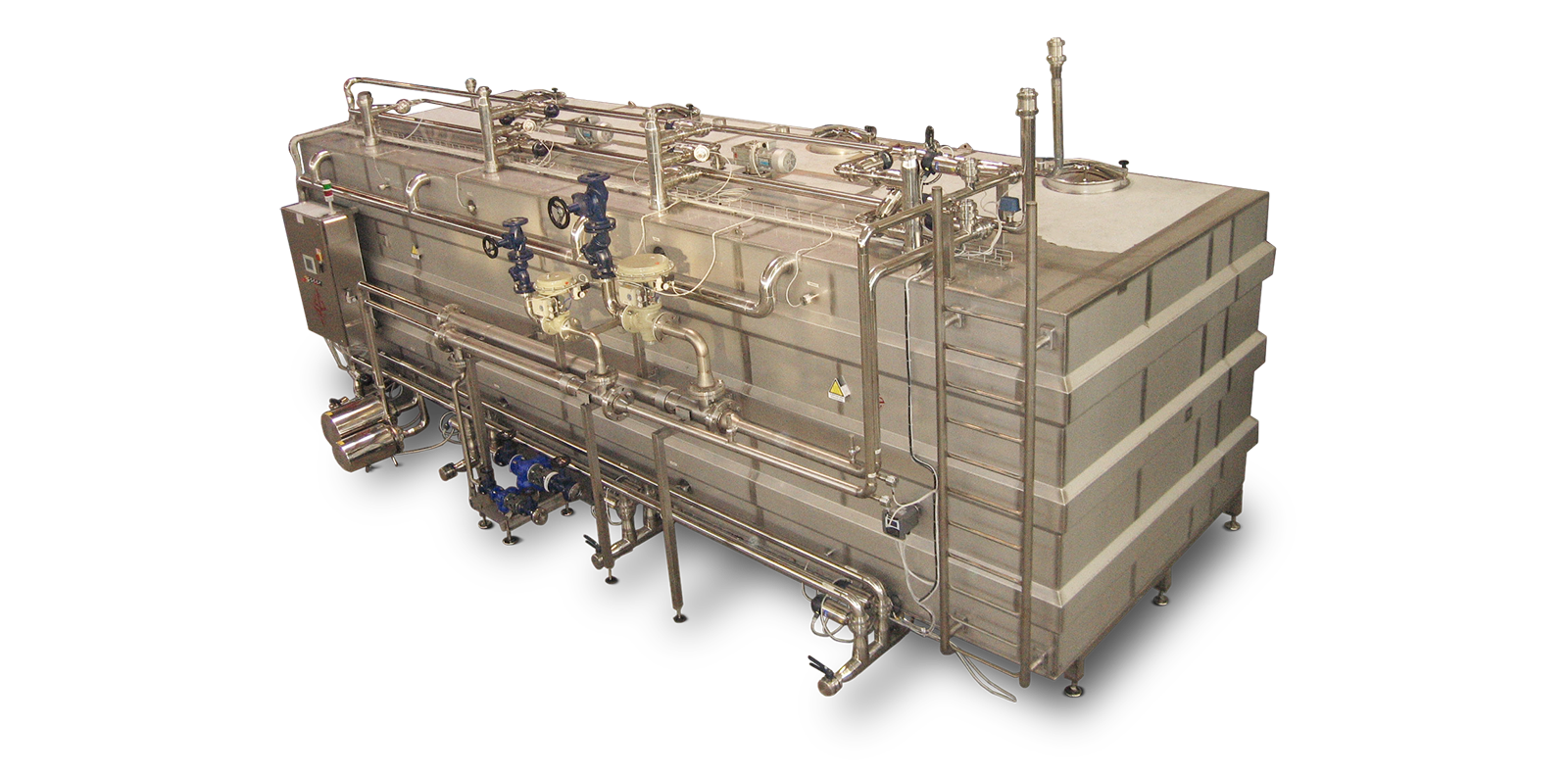

C.I.P. cleaning systems

When dealing with sanitization, it is possible to consider two fundamental operations: cleanse and disinfection of the machineries, especially piping, pumps, milk storage tanks, pasteurizer and any other kind of machinery that usually comes into contact with products. These operations and aspects are fundamental not only for the consumer’s protection, but also to avoid that the product’s quality could be affected by the presence of undesirable microbes able to alter the organoleptic characteristics of the product.

C.I.P. cleaning system is suitable for the automatic and sequential control of the cleaning program, with automatic choice of the washing pipelines. The system allows the setting of automatic washing that must be carried out at the end of the working phase and for every single unit. Moreover, it is possible to set up the washing in terms of temperature, percentage of detergents employed, rinse, duration of each step together with pressure. At the end of the cleaning cycle, the main measurements are going to be saved within the company’s network, namely information about temperature, scheduled washing time and percentage of detergents employed.

2-line C.I.P. cleaning

solid structure with horizontal fixed positioning / externally insulated tanks / regulation of steam temperature.

discharge pump with frequency converter / software for the automatic control of the cleaning steps / monitoring system for the cleaning data collection.

4-line C.I.P. cleaning system.

4-line C.I.P. cleaning system using soda and acid for milk storage reception.